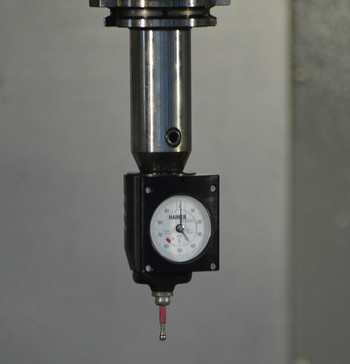

The first control is carried out at the end of the CAD process, before sending the file to the workshop.

We fill up a maths control report that compares the customer’s paper table or the 2d CAD to the dimensions of the 3d model which we have processed for the mould.

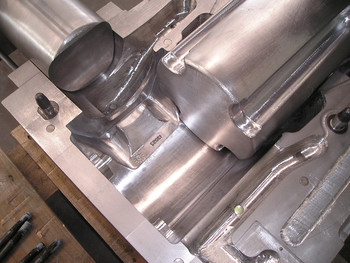

The final test is carried out through the casting of low-melting material into the chill.

With subsequent surveys and a marking out process, we control the critical dimensions of the casting, the swarfs, the thickness; deciding for the eventual improvements necessary to the figure.